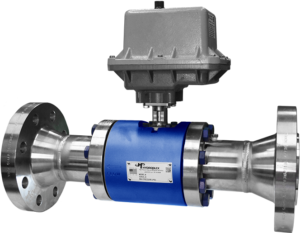

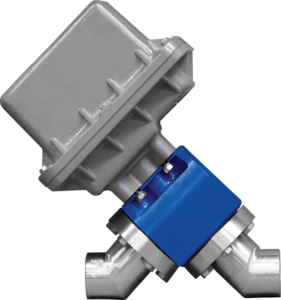

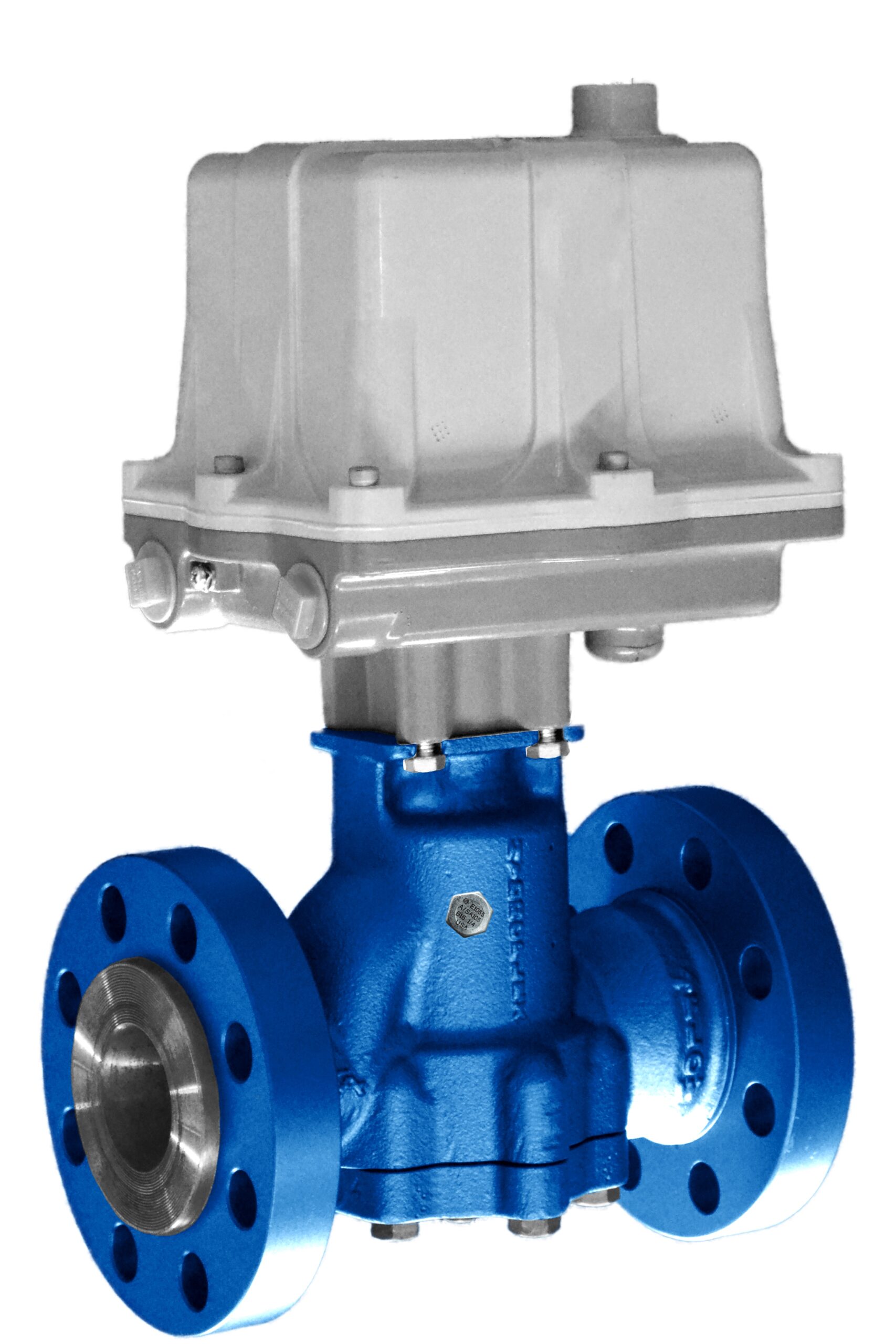

Hydroplex CSX TWIN DISC Valves are engineered with a specific purpose to manage high pressure liquids and gases, offering precise control, dependability, and prolonged service. The valve’s body and control element are designed to maximize the time between services. The modular design ensures that all worn-out parts can be replaced, making the valve easy to service and fully repairable. This valve is built to exceed your process requirements. The design is flexible enough to allow field conversions from manual to automated operations, and from single-stage to multistage pressure drop. An optional wear sleeve is available to mitigate the effects of cavitation and mechanical erosion, which are common in the fluid recovery process following pressure reduction. The unique hub design allows for a mix or match of inlet and outlet connections to suit process piping configurations or replacements due to wear.

Download PDF Brochure:

Features

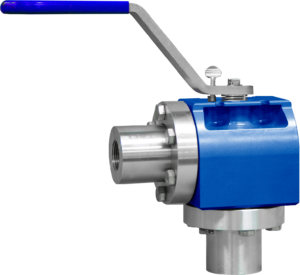

- Quarter-turn valves (90ᵒ full on/off)

- Actuated or Manual

- Injection/Chemical Port-1/4” NPT port for methanol/chemical injection of liquids or gasses for supplemental process improvements.

- High-quality materials

- Direct mount of the actuator to the valve body

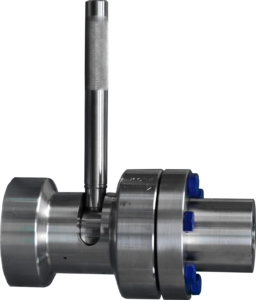

- Cartridge feature allows replacement of repair parts without breaking pipe or actuator connections

- Chemical Injection Port

- Standard ISO/DIN bolting pattern

- 5,000 MAWP

- 100% hydro-testing of all assemblies

- Low torque ratings

Applications

- Gas Lift Surface Valve

- Fluid Injection / Flow Control

- Manifold Pressure Control

- Gas & Condensate Production

- Separator Dump Valve

- Automated Throttle Valve

- Gas Lift Surface Choke

Additional Info

- Accessories: Stellite wear sleeve, Multistage pressure drop utilizing fixed orifice bean. Wear sleeve for added protection from abrasive or turbulent environments.

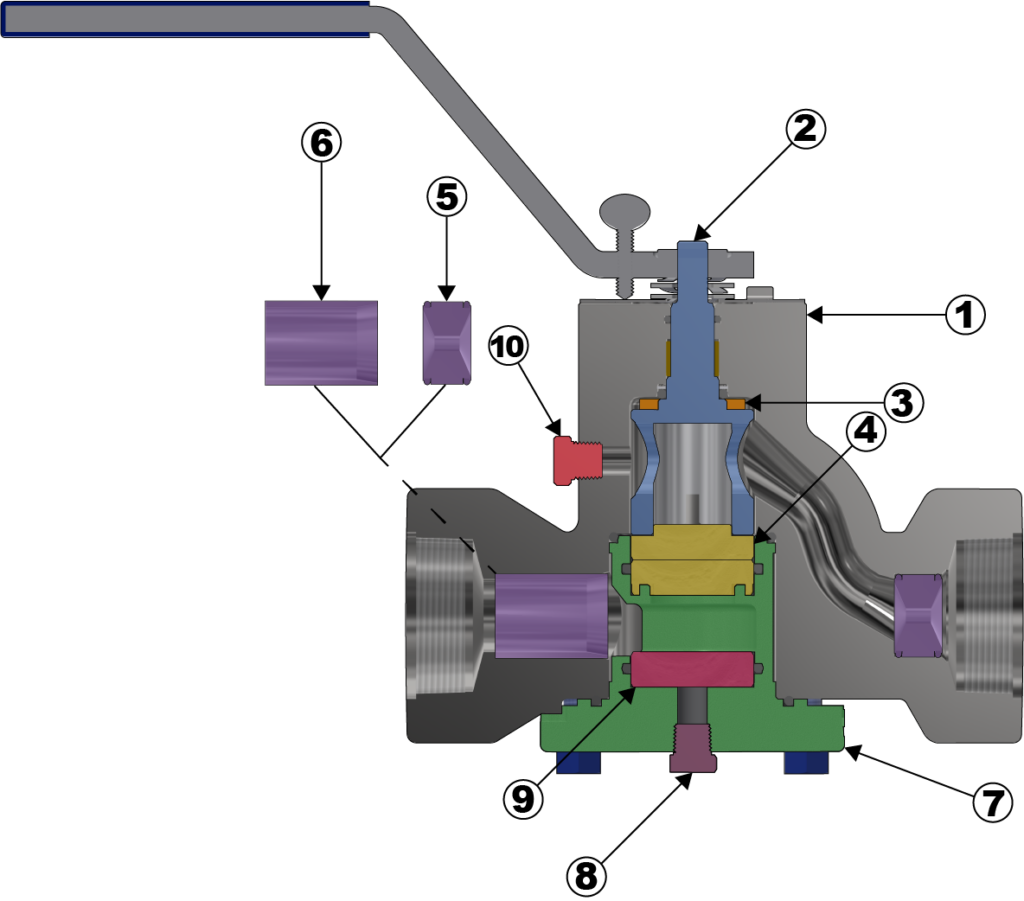

CSX Advanced Features

- Valve Body: Durable carbon steel body.

- Stem Assembly: The smaller shaft diameter reduces operating torque, requiring smaller and less expensive actuators.

- Thrust Bearing: This reduces the friction induced by pressure on the valve stem.

- Tungsten Control Discs: All valves come standard with Tungsten carbide trim available in sizes up to 3/4″.

- Fixed Orifice Bean (Optional): The hub design allows for placement of a fixed orifice bean to achieve up to a 3-stage pressure drop within the valve. The fixed orifice bean also extends the life of the valve.

- Wear Sleeve (Optional): The downstream wear sleeve, made of durable Stellite material, adds protection from abrasive or turbulent environments extending valve life.

- Cartridge Assembly: Holds in the wear components of the valve and allows for easy maintenance.

- Sensor Port: 1/8″ threaded port to allow for installation of a pressure sensor or gauge, or left open for wear detection.

- Wear Disc: This disc is meant to absorb energy from the change of direction of the fluid from the orifice discs to the valve outlet.

- Direct Actuator Mounting (Not Shown): Design allows for direct mounting of several common valve actuators without the need for couplings or brackets.

- 1/4″ NPT Port (Not Shown): Access port for optional injection of liquids or gasses for supplemental process improvements.