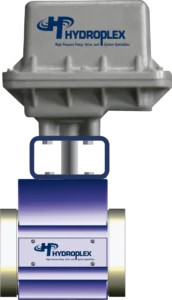

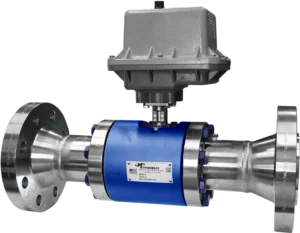

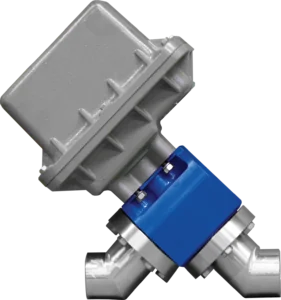

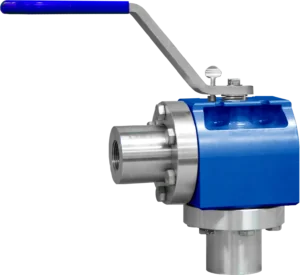

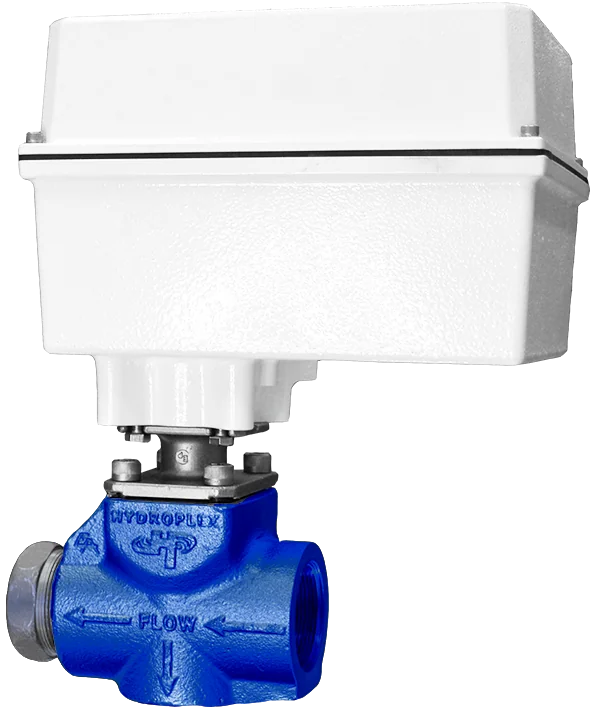

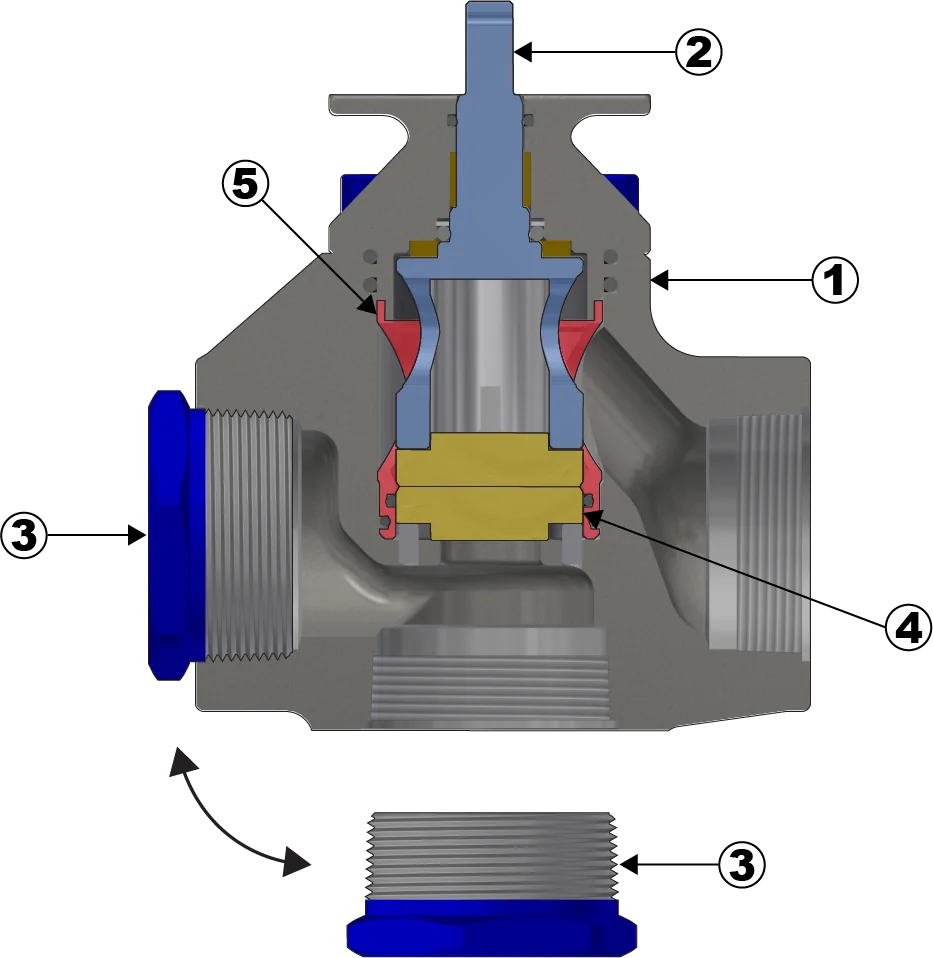

Hydroplex MiniMax is designed as quarter-turn, twin-disc throttling valves featuring two concentric discs that are diamond-polished, each with a pair of matching orifices. The configuration includes one fixed disc and another that rotates to modulate the flow path. This specialized trim is engineered for precise management of fluids and gases in demanding service conditions. The valve’s construction involves a minimal number of components prone to wear and achieves an ANSI class IV closure. These characteristics contribute to a robust design that simplifies fields servicing, extends operational lifespan, and lowers running expenses. Additionally, the valve’s adaptable design permits on-site modifications from manual to automated operation, even when the system is pressurized.

The Hyroplex MiniMax innovative line of throttling valves are long-lasting, powerful and versatile. MiniMax valves provide up to 3000 psi MAWP with direct mount actuation and convertible configuration. MiniMax valves are perfectly suited for a wide range of demanding applications including oilfield dump valves, water and gas injection, manifold pressure control, reverse osmosis, gas and condensate production, and more.

The MiniMax Twin Disc Throttling valves are specifically engineered for the regulation of water, oil, or natural gas flows. These valves can be enhanced with electric actuators to avert the atmospheric venting of control gas, a prevalent problem with diaphragm-operated control valves. This advanced design not only promotes environmental conservation but also offers marked improvements in both dependability and accuracy over pneumatic systems that utilize potentially contaminated natural gas sources. Equipped with an electric actuator, the MiniMax valve is designed for energy efficiency, operating effectively at 12 or 24VDC with a low current draw during activation. It is compatible with a variety of control signals, such as 4-20 mA, 1-5V, or a dry contact, and functions across a temperature spectrum of -30F to 350F (-34C to 177C). With the ability to manage The assembly is highly responsive full open to full closed in seconds. In the power failure mode valve can be configured to open, close or remain in position. No power is required to maintain the selected mode. The Hydra MiniMax valve offers a seamless transition from manual to automated operation in the field, without the need for service interruption. It features a Direct Mount ISO F07 pad and an ISO stem, which are compatible with most electric and pneumatic actuation systems. The conversion process is straightforward: simply remove the handle, place the actuator on top, and secure it with the four mounting bolts. Additionally, the valve’s low torque requirements minimize power consumption, making it an excellent choice for low voltage applications, including those powered by solar energy.

Download PDF Brochure:

Features

- Quarter turn valve (90 degrees full on/off)

- Direct mount actuation.

- Convertible Configuration: choose to plumb in-line or 90° right angle to fit your configuration.

- 3000 psi MAWP

- Rotary actuated – NO LIFTER REQUIRED!

- Control discs available in 6 sizes.

Applications

- Oilfield Dump Valve

- Water & Gas Injection

- Gas Lift/Plunger Lift

- Manifold Pressure Control

- Gas & Condensate Production

- Separator Letdown Valve

- Pump Start-up Bypass

- Separator Dump Valve

- Throttling Valve

- Disposal Wells

- Reverse Osmosis

MiniMax Advanced Features

- Valve Body: Durable carbon steel body.

- Stem Assembly: The smaller shaft diameter reduces operating torque, requiring smaller and less expensive actuators.

- Convertible Configuration: With Hex Plug placement, choose to plumb in-line or 90° right angle to fit your configuration.

- Tungsten Control Discs: All valves come standard with Tungsten carbide Trim available in sizes up to 3/4”.

- Assembly Cage: Allows for easy assembly and disassembly of all internal valve components.

- Direct Actuator Mounting (Not Shown): Design allows for direct mounting of several common valve actuators without the need for couplings or brackets.