What is a Hydrostatic Pressure Test Unit?

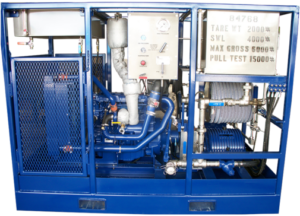

A hydrostatic test pump is a crucial component of a device known as a Hydrostatic Test Unit. Tests are conducted to ensure the strength, structural integrity and leak-proof nature of pressure vessels, pipelines, and gas cylinders. In this type of testing, the vessel or system is filled with water and pressurized to a level that exceeds its normal operating pressure.

Key Features of a Hydrostatic Test Unit Include:

- High-Pressure Testing Capability: Test pumps are designed to generate and sustain high pressures, allowing them to simulate the conditions the pressure vessel or system will face during normal operation.

- Adjustable Pressure Settings: These units often have adjustable pressure settings to allow for testing at various pressure levels, ensuring the equipment is tested across its full range. The hydrotest pump is pressure independent and designed to produce a pressure in excess of the maximum desired test pressure.

- Pressure Gauges: Most hydrostatic test units come equipped with pressure gauges to monitor and control the pressure during the testing process.

- Safety Features: Given the potential hazards associated with high-pressure testing, safety features are incorporated into these units. This may include relief valves to prevent over pressurization and other safety mechanisms.

- Portability: Testing units are often designed to be portable for ease of use in various locations.

- Hydrostatic Test Pumps can be driven by Electric Motor, Diesel or Gas Engine, Compressed Air or Hydraulic Motor.

- A Hydrostatic Test unit can feature a recording device for test documentation.

Hydrostatic testing is commonly required for compliance with industry standards and regulations, ensuring that pressure equipment meets safety and performance criteria. It helps identify potential weaknesses, defects, or leaks in the equipment under high-pressure conditions.

The testing procedure involves pressurizing the vessel or system to a specified pressure, holding that pressure for a designated period, and then observing whether there is any noticeable pressure drop or deformation. This process helps verify the integrity of the equipment and ensures it can safely handle the pressures it will encounter in its intended application.

Download PDF Brochure:

Features

- Two-stage operation

- Offshore ready

- Operates on 100 psi air or gas pressure

- 6 gpm fill pump units available to 30,000 psi

- Marine-grade aluminum cabinet

- Compact & lightweight

- Total weight less than 100 lbs.

- Can be incorporated into customer designed unit

- Can be easily adapted for chart recorder