In the face of growing environmental concerns, oil and gas producers are actively seeking innovative solutions to reduce emissions from their operations. This includes addressing methane emissions, eliminating non-emergency flaring, using low-emissions electricity to power upstream facilities, implementing carbon capture, utilization and storage technologies in oil and gas processes, and increasing the use of hydrogen from low- emissions electrolysis in refineries.

In response to these challenges, Hydroplex has introduced the HYDRA Series product line as part of its “Green” initiative. This application includes an energy-efficient “Electric” actuator and throttling valve. With the help of the Smart actuator, this valve provides “feed forward and feed back” control, enabling producers to optimize their processes, thereby enhancing efficiencies and production levels.

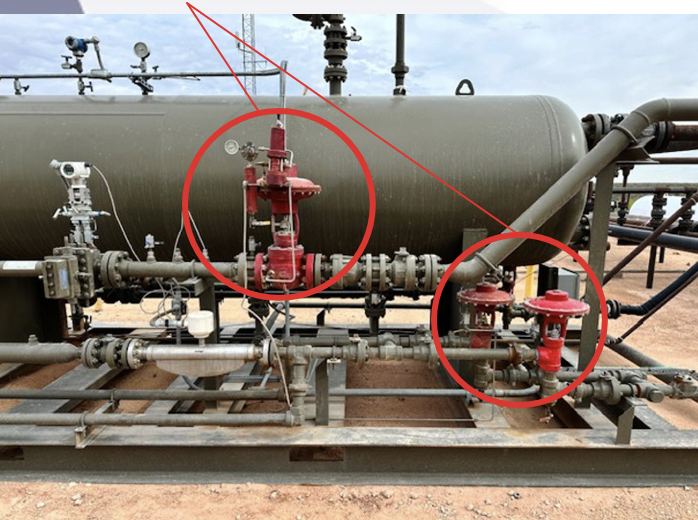

Hatfield and Company, a Hydroplex distributor in West Texas, has demonstrated the effectiveness of these solutions. As shown in the accompanying photographs, they have replaced the traditional gas-operated diaphragm valves on a horizontal separator with a Hydroplex Model CSX and two Hydroplex Model MiniMax throttling valves for one of their clients. This modification not only addresses emission concerns but also enhances remote visibility of valve operations and offers opportunities for managing and optimizing wellsite processes.

Conventional Diaphragm Valves

Hydroplex Energy Efficient Electric Throttling Valves

Photographs contributed by John Acton, Hatfield and Company